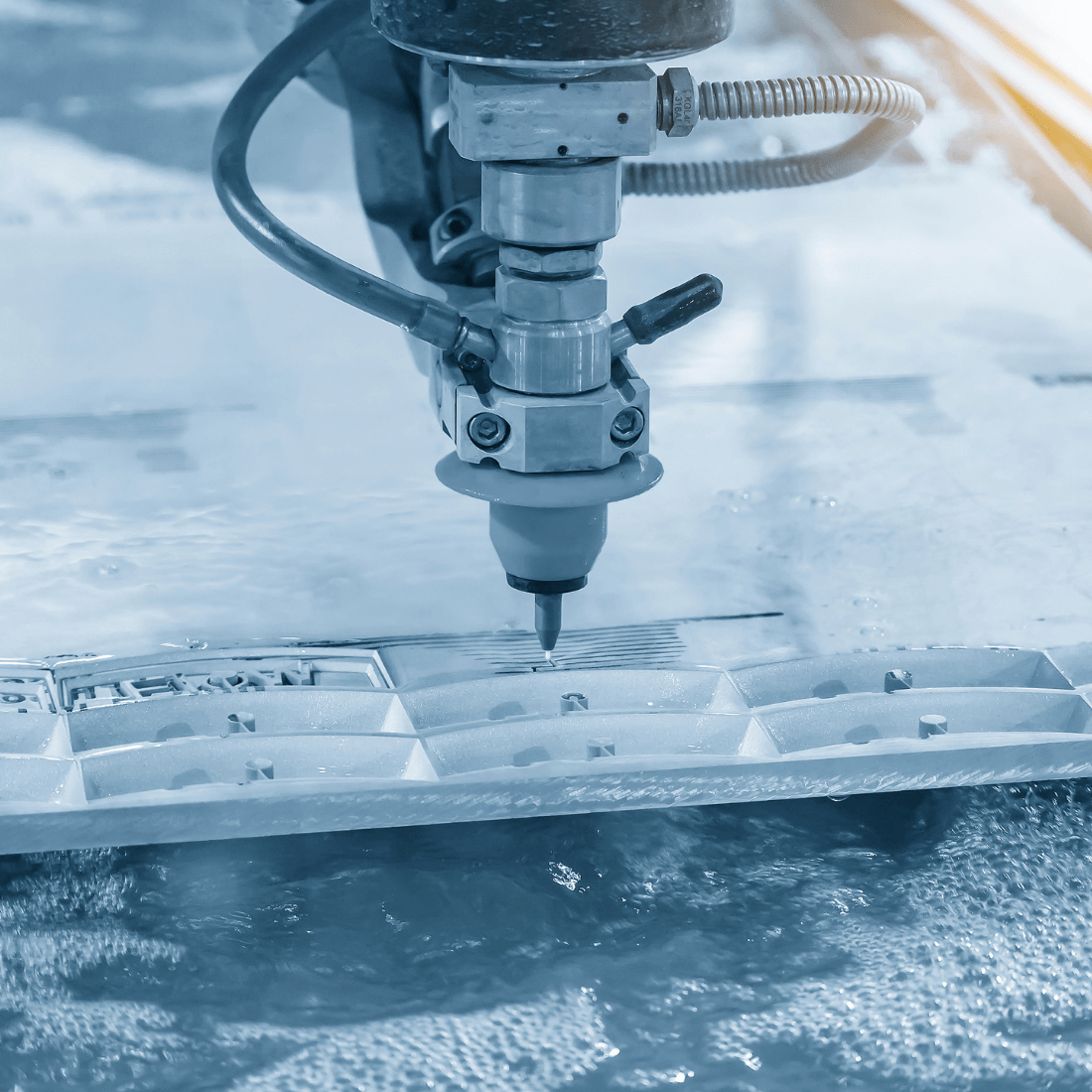

In the diverse world of manufacturing, adaptability and precision are key. Waterjet cutting, a versatile and efficient cutting method, stands out as a prime example of technology that meets these needs. Utilizing high-pressure water mixed with abrasives, waterjet cutting can slice through a variety of materials with remarkable accuracy. This blog post will explore the unique advantages and applications of waterjet cutting in modern manufacturing.

Understanding Waterjet Cutting: Waterjet cutting is a non-thermal cutting method that uses a high-velocity jet of water, often mixed with abrasive particles, to cut through materials.

- Precision Cutting Without Heat: One of the significant advantages of waterjet cutting is its ability to cut without generating heat, thereby avoiding material distortion or warping.

- Wide Range of Materials: From metals and composites to glass and stone, waterjet cutting can handle an impressive array of materials, making it a versatile tool in any manufacturing setting.

- Complex Cuts Made Easy: The precision and flexibility of waterjet cutting make it ideal for creating intricate designs and shapes that would be challenging with other cutting methods.

Advantages of Waterjet Cutting in Manufacturing: Waterjet cutting offers several benefits that make it a preferred choice in various manufacturing scenarios.

- No Material Limitations: Unlike some cutting methods that are limited to specific types of materials, waterjet cutting is remarkably versatile, capable of handling almost any material.

- Environmentally Friendly: As a cold-cutting process, waterjet cutting doesn’t produce hazardous waste or gases, making it an environmentally friendly option.

- High Precision and Reduced Finishing Time: The accuracy of waterjet cutting often eliminates the need for secondary finishing processes, saving time and resources.

Applications Across Industries: The adaptability of waterjet cutting has led to its widespread use across various industries.

- Aerospace and Automotive: For industries where precision is non-negotiable, waterjet cutting is used to produce intricate parts with tight tolerances.

- Art and Architecture: The ability to cut complex patterns and designs makes waterjet cutting a favorite in the art and architectural fields.

- Custom Fabrication: Its flexibility makes waterjet cutting ideal for custom projects, allowing for unique designs and prototypes.

Waterjet cutting is more than just a cutting process; it’s a solution that offers precision, versatility, and environmental sustainability. Its ability to handle a wide range of materials and complex designs makes it an invaluable tool in the modern manufacturing toolkit.

At SchGo Engineered Products, we are proud to offer advanced waterjet cutting services. Our expertise ensures that our clients receive components that meet the highest standards of quality and precision.

Are you looking to leverage the benefits of waterjet cutting for your manufacturing needs? Contact SchGo Engineered Products today and discover how our waterjet cutting solutions can elevate your production capabilities. Let’s cut through the challenges together with precision and innovation!