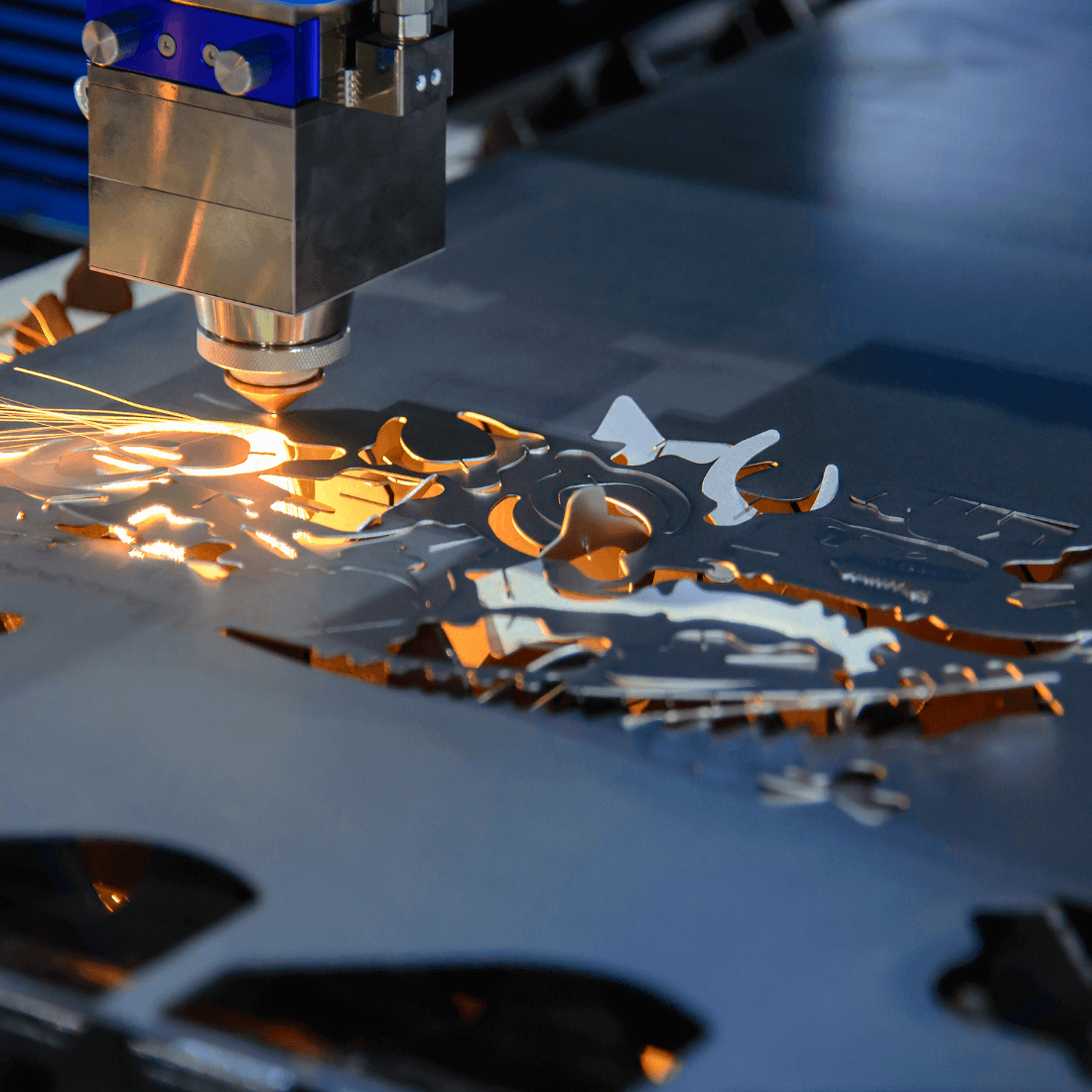

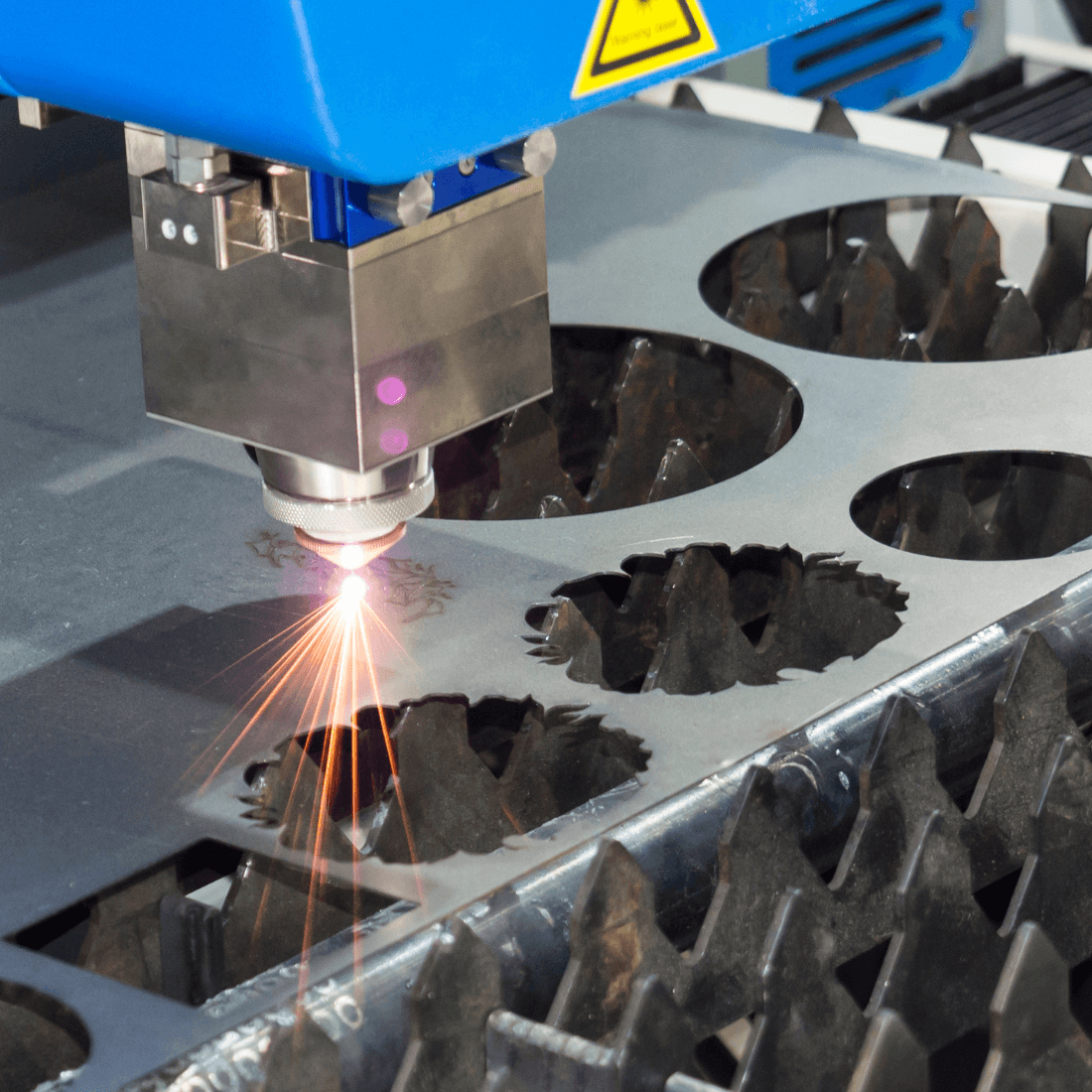

SchGo Engineered Product, Inc. provides laser cutting service by way of a Salvagnini L5 fiber laser cutting system. The l5 is the machine that Salvagnini has dedicated exclusively to fiber. Its cutting-edge technology means that it is able to reach the very highest levels in terms of speed, accuracy, reliability, and performance to SchGo’s facility. Combined with the experience of SchGo’s laser team, this technology allows us to outperform our competition. All Salvagnini laser machines feature revolutionary mechanical and control solutions, together with original programming and nesting software, this allows us at SchGo to tackle any project, from multi part and piece nests, to simple one part cuts.

Salvagnini has taken Fiber Laser technology to the next level, adding their patented mechanical drive system consisting of a compass structure, made possible due to the fiber lasers absence of a defined optical path. This allows our machine to move with dynamics of up to 5Gs and use less power to do so, due to the less weight of this head.