In the world of manufacturing, the quest for precision, speed, and versatility leads us to one standout solution: CNC (Computer Numerical Control) Machining. This technology has become the backbone of modern manufacturing, offering unparalleled accuracy and efficiency in producing parts and components. In this blog post, we’ll delve into the world of CNC machining and its pivotal role in today’s manufacturing landscape.

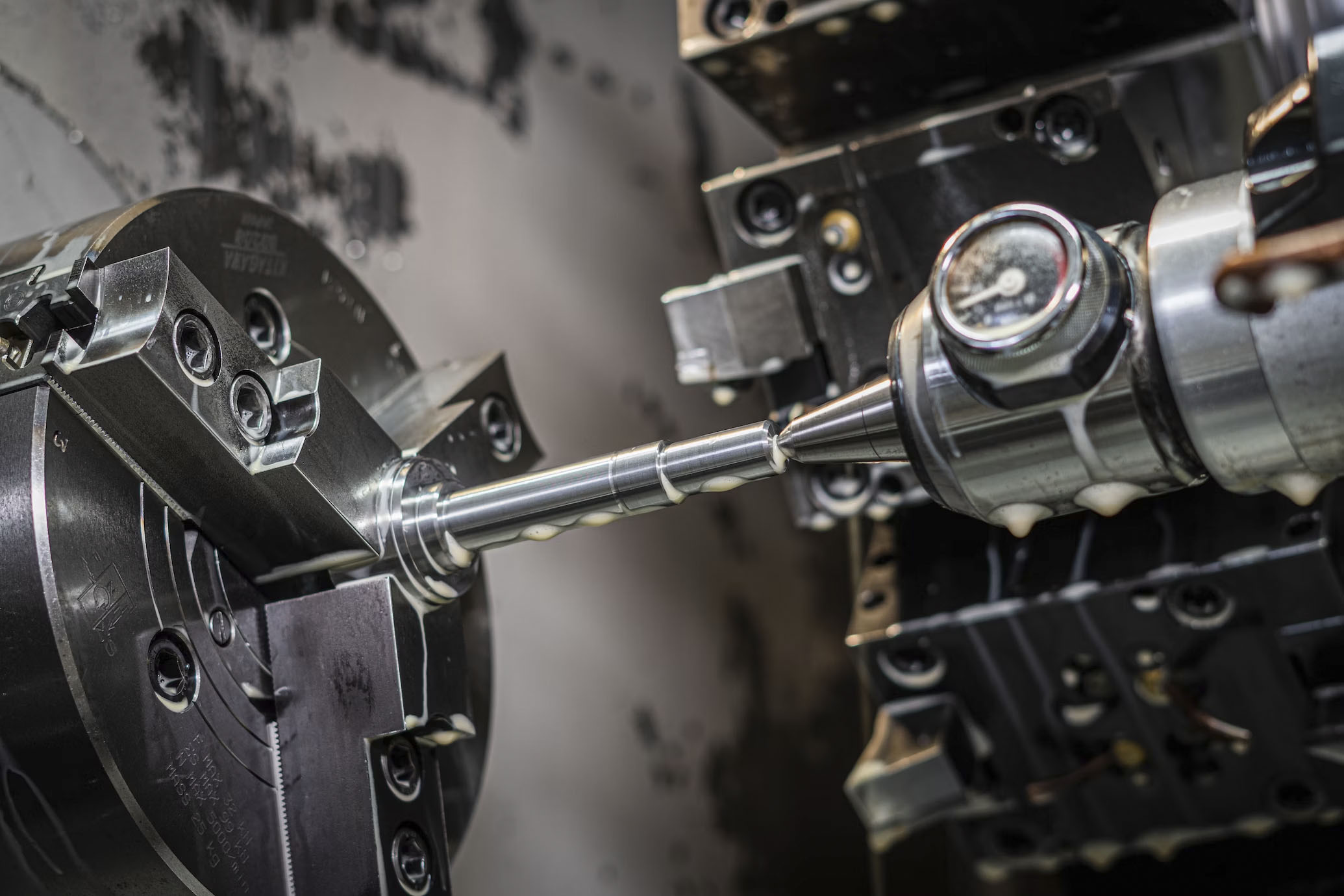

The Core of CNC Machining: CNC machining is a subtractive manufacturing process where computer-controlled machine tools remove layers from a solid block of material to shape the desired part.

- Precision at Its Finest: CNC machines operate with exceptional accuracy, making them ideal for creating parts with tight tolerances and intricate details.

- Versatility Across Materials: From metals to plastics and composites, CNC machining can handle a wide array of materials, catering to the diverse needs of various industries.

- Complex Designs Made Simple: The advanced capabilities of CNC machines allow for the production of complex and sophisticated designs that would be challenging or impossible to achieve with manual machining.

Transforming Manufacturing with CNC: CNC machining is not just a process; it’s a transformational tool that has reshaped how we approach manufacturing.

- Enhanced Productivity: With CNC machining, operations can run continuously with minimal supervision, significantly boosting productivity and efficiency.

- Consistency and Reproducibility: CNC machines ensure that each part is produced with the same high level of precision, essential for large-scale production runs where consistency is key.

- Reduced Lead Times: The speed and efficiency of CNC machining mean faster production times, enabling quicker turnaround for projects and a competitive edge in the market.

CNC Machining in Various Industries: The versatility of CNC machining makes it a critical component in numerous sectors.

- Aerospace and Automotive: These industries rely on CNC machining for producing complex, high-precision components that meet strict safety and quality standards.

- Medical Devices: CNC technology is used to create precise and reliable medical instruments and implants.

- Custom Fabrication: The adaptability of CNC machining is perfect for custom projects, allowing for personalized designs and prototypes.

CNC machining stands at the forefront of manufacturing innovation. Its ability to deliver precision, speed, and versatility makes it an indispensable tool in the modern manufacturing arena. As technology continues to advance, CNC machining will undoubtedly play a crucial role in shaping the future of production.

At SchGo Engineered Products, we harness the full potential of CNC machining to meet and exceed our clients’ expectations. Our commitment to precision and excellence ensures that every project we undertake is a step towards redefining manufacturing standards.

Elevate your manufacturing process with the precision and efficiency of CNC machining. Contact SchGo Engineered Products today to discover how our CNC solutions can transform your production capabilities. Let’s build the future of manufacturing together!