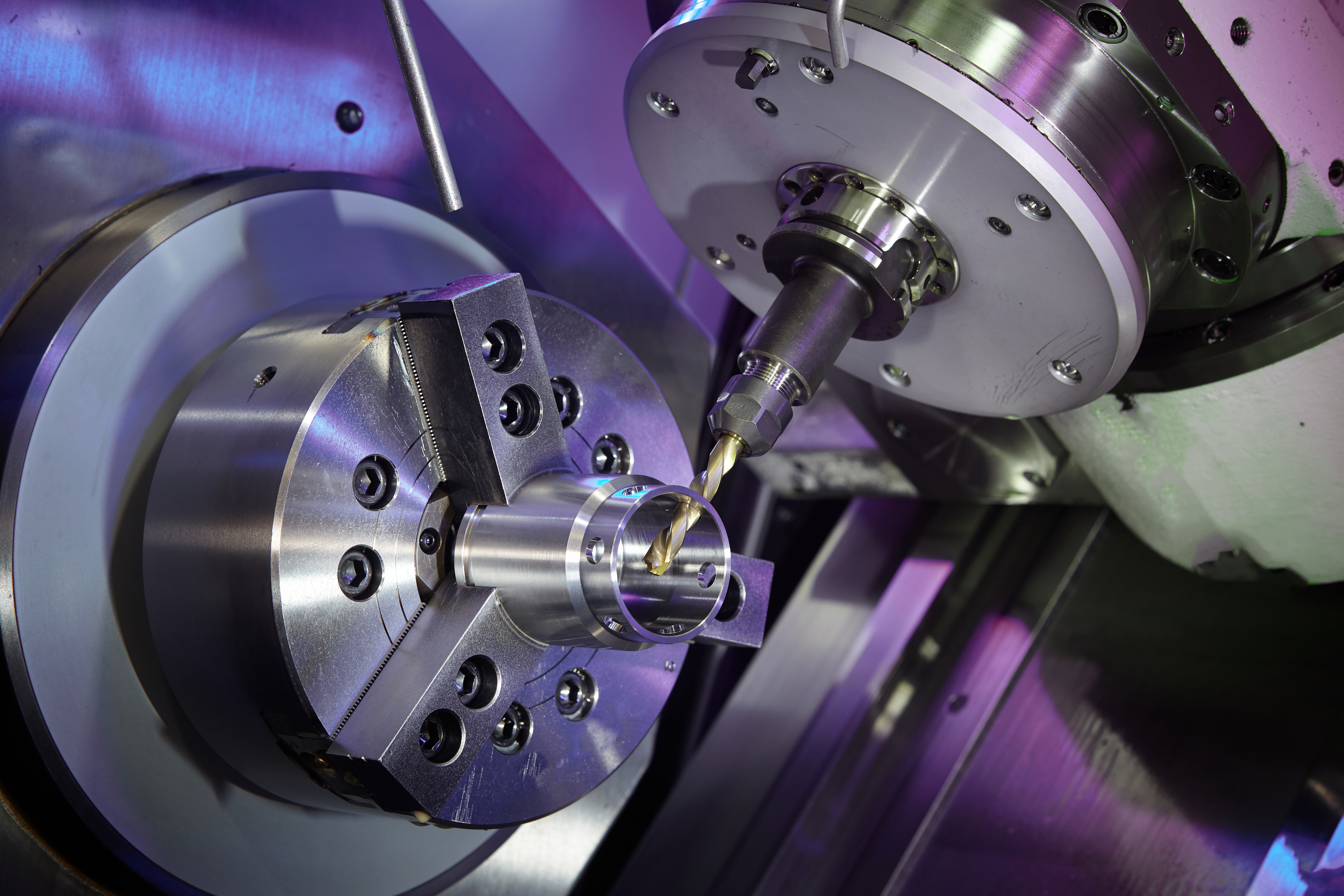

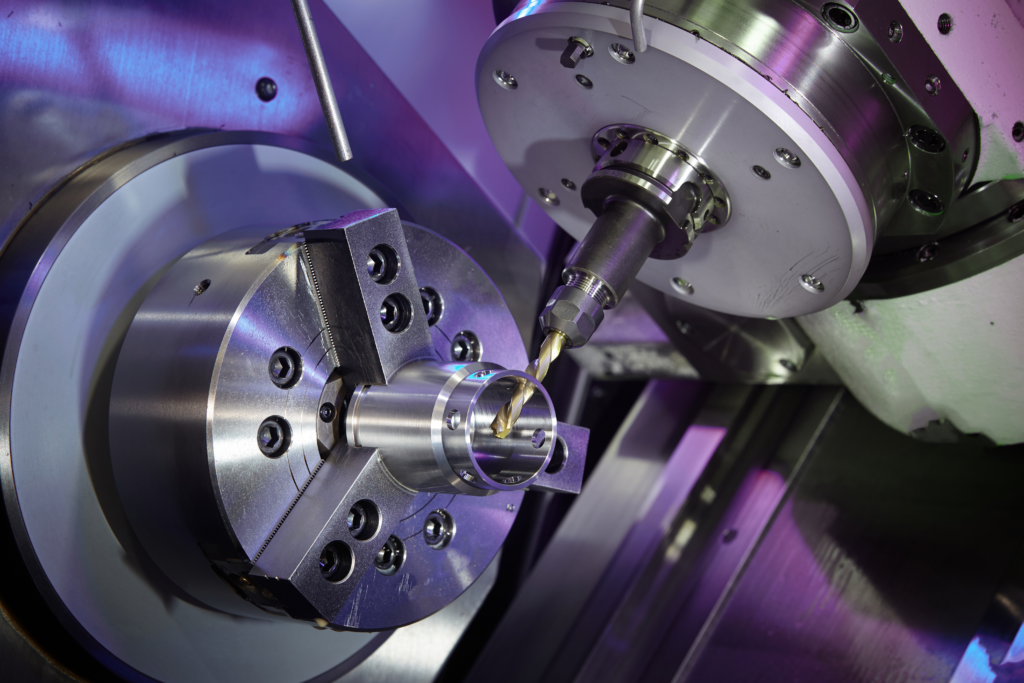

The journey of CNC (Computer Numerical Control) machining from its inception to the advanced applications we see today is a testament to the relentless pursuit of precision, efficiency, and innovation in the manufacturing industry. SchGo Engineered Products, with years of expertise and a commitment to excellence, has been at the forefront of adopting and refining these technologies. In this article, we explore the evolution of CNC machining, shedding light on its impact and the advanced applications it has enabled.

The Origins of CNC Machining

CNC machining’s roots can be traced back to the 1940s and 1950s when the first numerical control (NC) machines were developed. These machines used punched tape to direct the movements of machinery tools, marking a departure from manual control to automated processes. However, it was the introduction of computers in the control process that truly revolutionized machining. CNC machining brought about unparalleled accuracy and repeatability, allowing for complex parts to be manufactured with minimal human intervention.

The Transition to CNC

The transition from NC to CNC machining was fueled by advancements in computer technology and software development. This transition marked a significant leap in the capabilities of machining equipment. CNC machines could now process complex instructions via computer programs, execute precise movements, and produce parts with intricate geometries that were previously impossible or too costly to achieve.

Advancements in CNC Technology

Over the years, CNC technology has seen significant advancements, including:

- Enhanced Precision: Modern CNC machines offer incredibly high precision and consistency, with tolerances as tight as a few micrometers.

- Increased Speed and Efficiency: Faster processing power and more efficient software algorithms have reduced machining times and improved throughput.

- Versatility: CNC technology now caters to a wide range of materials and processes, from metal milling and turning to 3D printing and laser cutting.

- Automation and Integration: CNC machines can be integrated into larger automated systems, contributing to the rise of smart factories and Industry 4.0.

- User-Friendly Interfaces: Advances in software have made CNC machines more accessible, with intuitive interfaces and simulation tools.

Advanced Applications of CNC Machining

CNC machining’s evolution has expanded its applications far beyond traditional manufacturing sectors. Some of the advanced applications include:

- Aerospace and Defense: Manufacturing critical, high-tolerance components for aircraft and military hardware.

- Medical Devices: Creating complex, custom, and highly precise instruments and implants.

- Automotive Industry: Producing a wide range of components, from prototypes to final parts for high-performance vehicles.

- Custom and Prototype Manufacturing: Enabling cost-effective production of custom parts and prototypes, accelerating product development cycles.

SchGo Engineered Products: Pioneering Advanced CNC Applications

At SchGo Engineered Products, we pride ourselves on leveraging the full spectrum of CNC machining capabilities to serve a diverse array of industries. Our state-of-the-art equipment, combined with our team’s deep expertise, allows us to tackle projects ranging from simple parts to complex assemblies with stringent requirements. We continuously explore new ways to apply CNC technology, pushing the boundaries of what can be achieved in precision manufacturing.

Looking Ahead

The future of CNC machining promises even greater advancements with the integration of artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies will further enhance precision, efficiency, and automation, opening new avenues for innovation in manufacturing.

SchGo Engineered Products remains committed to staying at the cutting edge of CNC technology. We are dedicated to delivering solutions that meet the evolving needs of our clients, ensuring precision, efficiency, and reliability.

For those seeking a partner to navigate the complexities of modern manufacturing, look no further than SchGo Engineered Products. Contact us at 951-272-8089 to discuss how we can bring your projects to life with the advanced capabilities of CNC machining.