Welcome to SchGo’s exploration of precision machining techniques. In the world of manufacturing, precision machining is the cornerstone of producing high-quality components with accuracy, repeatability, and efficiency. In this guide, we’ll delve into advanced machining techniques and methodologies that will empower you to achieve precision and excellence in your machining processes. From multi-axis machining to high-speed cutting and beyond, let’s uncover innovative approaches that will take your machining capabilities to new heights.

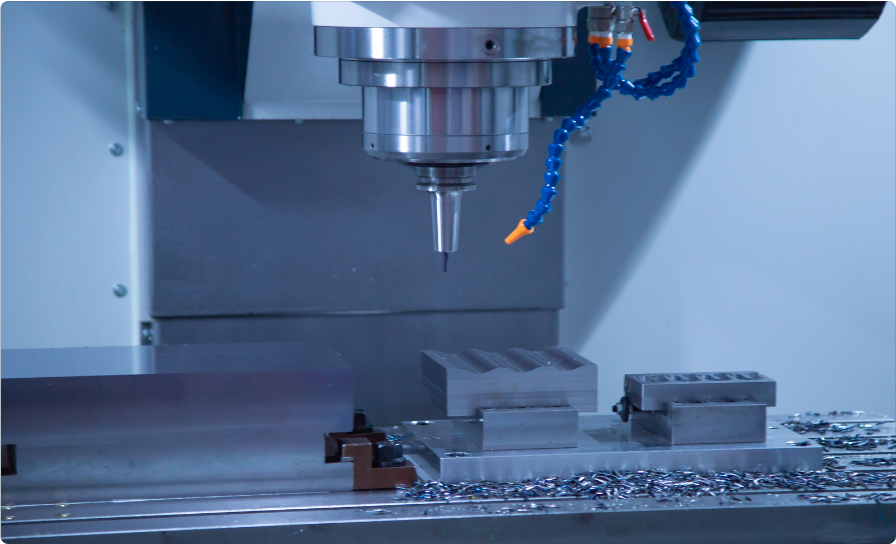

Understanding Precision Machining Techniques: Precision machining encompasses a range of techniques and methodologies that enable the production of complex components with tight tolerances and exceptional surface finishes. From traditional milling and turning operations to advanced technologies such as multi-axis machining and high-speed cutting, precision machining techniques are continually evolving to meet the demands of modern manufacturing.

Exploring Advanced Machining Techniques:

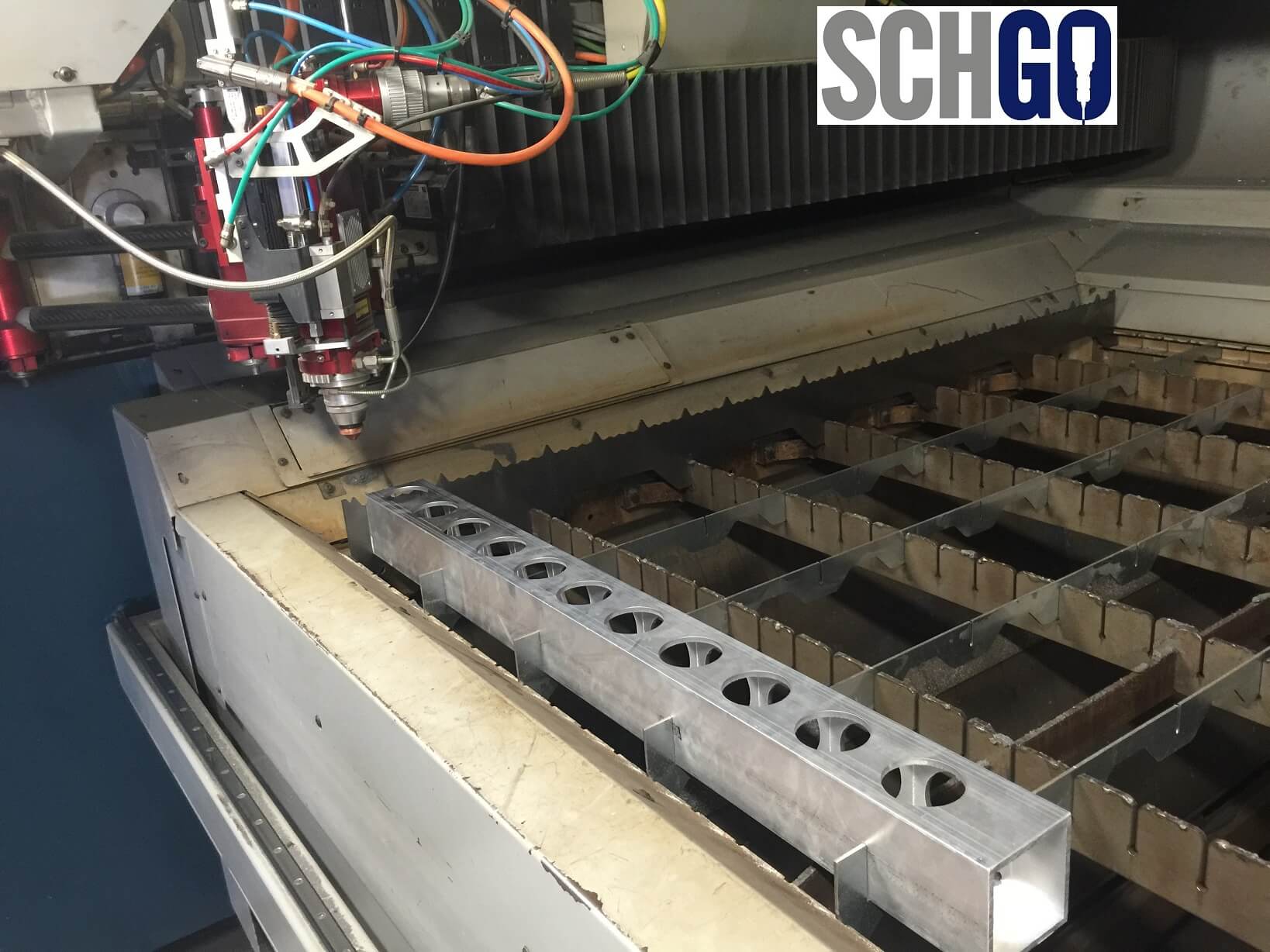

- Multi-Axis Machining: Multi-axis machining enables simultaneous cutting in multiple directions, allowing for the production of complex geometries with unparalleled precision. By leveraging the capabilities of multi-axis CNC machines, engineers can reduce setup times, improve surface finish quality, and achieve tighter tolerances compared to conventional machining methods.

- High-Speed Cutting (HSC): High-speed cutting (HSC) is a machining technique that involves cutting at significantly higher speeds and feed rates than conventional machining processes. By utilizing specialized cutting tools and optimized machining parameters, HSC allows for faster material removal rates, improved surface finish quality, and reduced machining forces, resulting in higher productivity and efficiency.

- Computer-Aided Manufacturing (CAM) Optimization: Computer-aided manufacturing (CAM) software plays a crucial role in optimizing machining processes by generating efficient toolpaths and optimizing machining parameters. By leveraging advanced CAM techniques such as toolpath optimization, adaptive machining, and toolpath simulation, engineers can maximize material removal rates, minimize tool wear, and achieve superior surface finish quality.

- Hard Machining: Hard machining involves the machining of hardened materials such as hardened steels, tool steels, and ceramics. By utilizing specialized cutting tools and machining techniques such as hard milling and hard turning, engineers can achieve precise dimensional accuracy and surface finish quality in hardened materials, eliminating the need for secondary finishing operations.

Implementing Innovative Approaches: To incorporate advanced machining techniques into your operations, it’s essential to stay abreast of the latest technological advancements and industry trends. Consider investing in state-of-the-art CNC machines, cutting tools, and CAM software, and provide ongoing training and development opportunities for your machining personnel to ensure they have the skills and knowledge to effectively utilize advanced techniques.

Precision machining is an ever-evolving field, driven by innovation, technology, and a relentless pursuit of excellence. By exploring advanced machining techniques and methodologies, you can unlock new opportunities for achieving precision and efficiency in your machining processes. At SchGo Engineered Products, we’re committed to pushing the boundaries of precision machining and empowering our customers with the tools, knowledge, and expertise they need to succeed.