Choosing the right materials for CNC machining projects is essential to achieving optimal results. The materials you select can impact factors such as machining performance, part quality, and overall project success. In this blog post, we’ll explore key considerations for selecting materials for CNC machining projects and offer guidance to help you make informed decisions.

Understanding Material Properties: Before selecting materials for CNC machining projects, it’s essential to understand their properties and characteristics. Different materials exhibit varying levels of hardness, strength, ductility, and thermal conductivity, which can influence machining performance and part functionality. By considering material properties, you can choose materials that are well-suited to your specific application requirements.

Matching Materials to Application Requirements: When selecting materials for CNC machining projects, it’s crucial to consider the specific requirements of your application. Factors such as mechanical strength, corrosion resistance, thermal stability, and electrical conductivity should guide your material selection process. By matching materials to application requirements, you can ensure that your parts perform optimally in their intended environment.

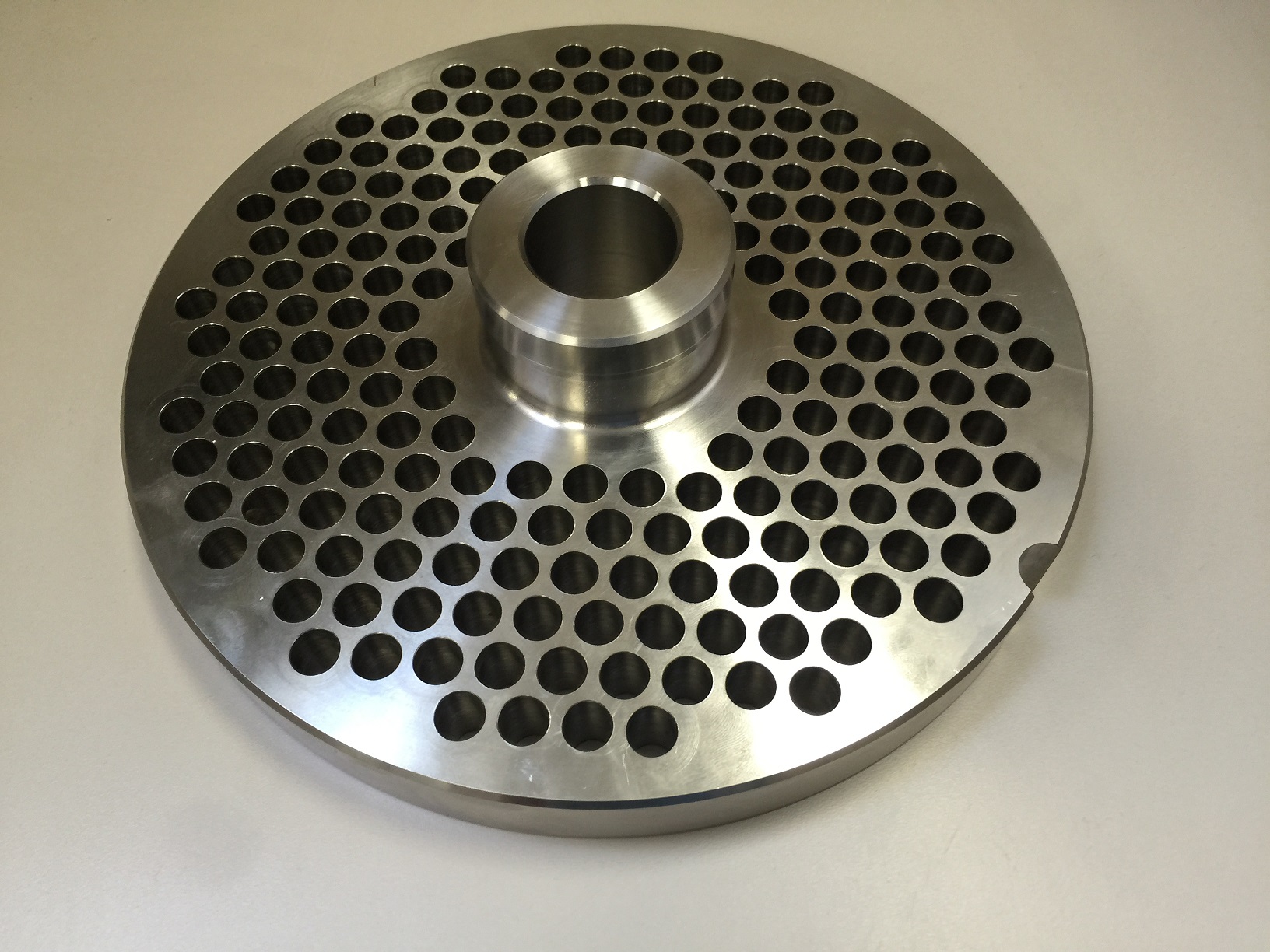

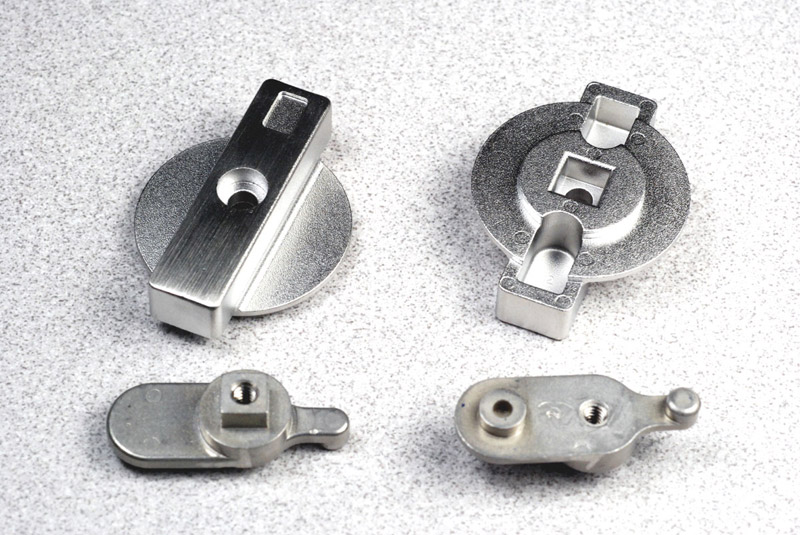

Evaluating Machinability: Machinability refers to the ease with which a material can be machined using CNC processes. Some materials, such as aluminum and brass, are known for their excellent machinability, while others, like stainless steel and titanium, are more challenging to machine. Consider the machinability of different materials when selecting them for CNC machining projects to minimize tool wear, machining time, and production costs.

Considering Cost and Availability: Cost and availability are practical considerations that should inform your material selection decisions. While certain materials may offer desirable properties for your application, they may also come with higher costs or limited availability. Evaluate the cost-effectiveness and accessibility of materials to ensure they align with your project budget and timeline constraints.

Exploring Material Options: The market offers a wide range of materials suitable for CNC machining projects, including metals, plastics, composites, and exotic alloys. Each material has its unique properties, advantages, and limitations, making it essential to explore your options thoroughly. Consider factors such as material availability, lead times, and supplier reliability when evaluating different material options for your CNC machining projects.

Choosing the right materials for CNC machining projects is a critical step in achieving success. By understanding material properties, matching materials to application requirements, evaluating machinability, considering cost and availability, and exploring material options, you can make informed decisions that lead to optimal project outcomes. At SchGo Engineered Products, we’re here to support you in selecting the right materials for your CNC machining projects and achieving your manufacturing goals.